Common Bearing Materials

Common Bearing Materials

Blog Article

Selecting the right bearing material is crucial for enhancing performance and longevity in mechanical systems. With countless applications—ranging from automotive to aerospace—understanding the different types of bearing materials can make a significant difference in efficiency and durability. Factors such as load capacity, environmental conditions, and friction levels all play a vital role in this decision-making process.

Common Bearing Materials

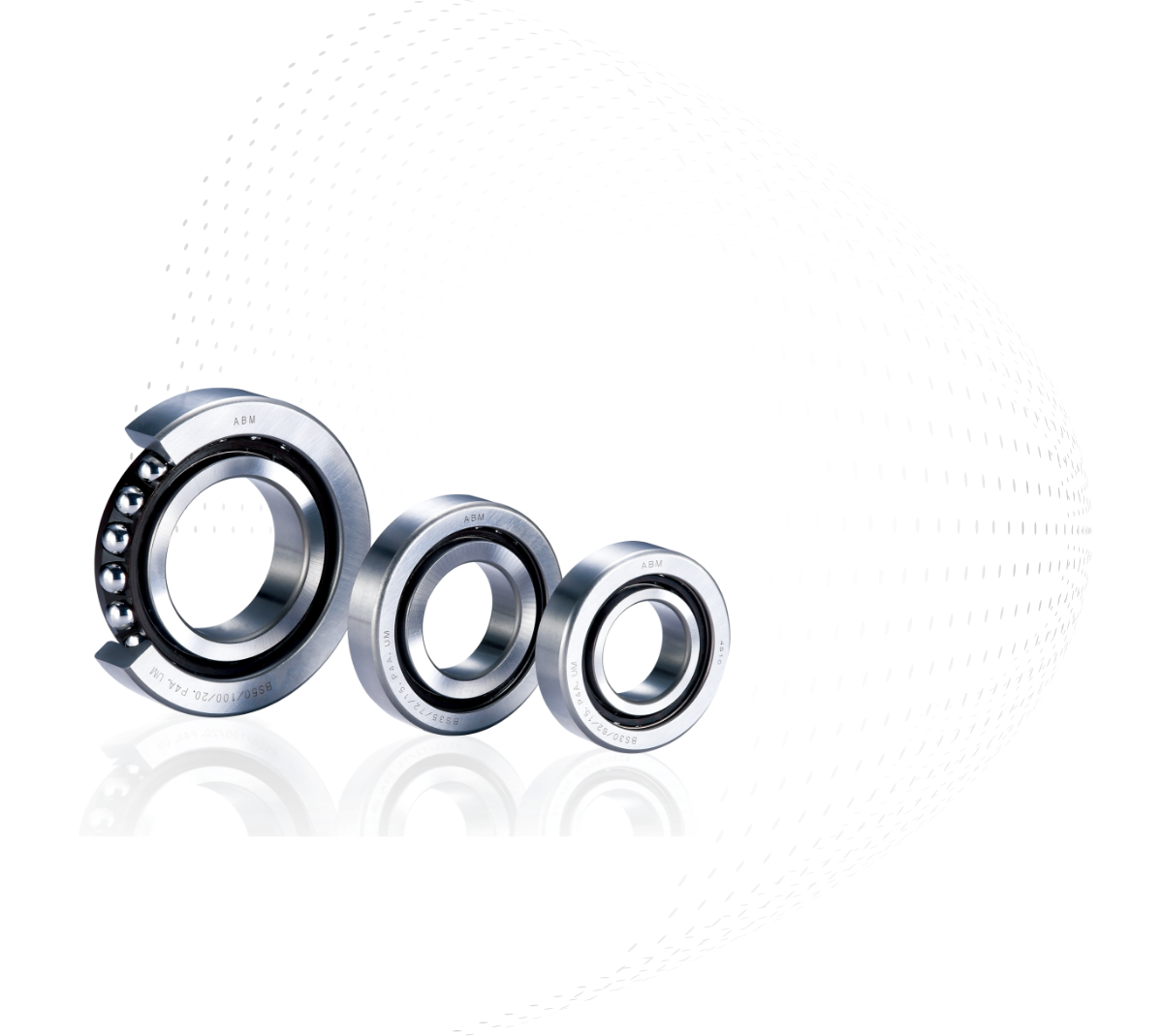

Bearings are predominantly made from several key materials, each offering unique benefits and drawbacks. The most common materials include steel, brass, plastic, and ceramic. Each material has specific characteristics that make it suitable for particular applications.

Steel Bearings

Steel is perhaps the most widely used material for bearings. Its high strength and durability make it ideal for heavy-load applications. Steel bearings typically come in two forms: carbon steel and stainless steel. Carbon steel offers excellent hardness and wear resistance but is susceptible to rust. In contrast, stainless steel provides corrosion resistance, making it a popular choice in environments exposed to moisture or chemicals. For example, in marine applications, stainless steel bearings can withstand harsh saline conditions without degrading.

Brass Bearings

Brass bearings are another option, known for their excellent machinability and good wear resistance. These bearings perform well in medium-load applications and provide a degree of self-lubrication, reducing friction. Brass is often found in electronic applications and automotive components, where both conductivity and durability are required.

Plastic Bearings

Plastic bearings are gaining popularity due to their lightweight nature and resistance to corrosion and chemicals. They are particularly useful in applications involving food processing or pharmaceuticals, where hygiene is paramount. These bearings also operate silently, making them ideal for household appliances. However, they generally have lower load capacities compared to metal options.

[IMAGE]

Ceramic Bearings

Ceramic bearings represent the pinnacle of bearing technology. Known for their exceptional hardness and low friction properties, ceramics can perform in extreme conditions, including high speeds and temperatures. They are often used in high-performance applications, such as racing bikes and aerospace components. While their cost is higher than other materials, the long-term benefits often outweigh the initial investment.

Choosing the Right Material

The decision on which bearing material to use hinges on several factors, including operational conditions, load requirements, and environmental exposure. For example, if you are working in an environment that experiences high temperatures and corrosive chemicals, a ceramic or stainless steel bearing would be more suitable. Conversely, for applications requiring light loads and minimal friction, plastic bearings may be the best choice.

Another consideration is maintenance. Some materials, like brass and plastic, may require less upkeep than steel, which can rust and corrode if not properly lubricated. An informed choice can save costs in both maintenance and replacements over time.

For detailed guidance on Bearing material options tailored to your specific needs, consult with industry experts or manufacturers who can provide insights into the best materials for your applications.

Conclusion

In summary, the choice of bearing material has profound implications on the performance and longevity of mechanical systems. Steel, brass, plastic, and ceramic each have their own strengths and weaknesses. Understanding these differences is essential for optimizing your machinery's efficiency and ensuring its reliability in demanding environments.

Report this page